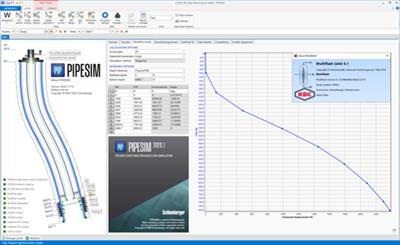

The Schlumberger development team is pleased to announce the availability of PIPESIM 2020.1 is new generation software in multiphase flow simulation to overcome fluid flow challenges and optimize production.

Schlumberger PIPESIM 2020.1 | 598.8 mb

What's new in Schlumberger PIPESIM 2020.1

Highly accurate VPC method added for gas lift valve performance

PIPESIM 2020.1 offers an option for members of Valve Performance Clearinghouse (VPC) to calculate the performance of gas lift valves using the VPC method and valve catalog. Compared with traditional methods, the VPC method provides a more accurate calculation of the gas flow pattern past the stem and seat and valve throughput. The VPC gas lift valve catalog is owned by Louisiana State University (LSU). The full catalog includes valves from several manufacturers, and you need to contact LSU for access.

Gas lift multipointing now available in System Analysis task

In PIPESIM 2019.1, the option to determine if gas lift injection occurs through several valves (multipointing) was introduced for the P/T profile task. In PIPESIM 2020.1, this option is also now available for the System Analysis task. The option takes into consideration the surface injection pressure and temperature, injection rate, frictional pressure gradient in the annulus, and possible throttling of the gas lift valves.

Native support of risk indications of erosion and corrosion

In PIPESIM 2020.1, the erosion and corrosion risks plug-in functionality is included as a native feature. The functionality associates ranges of corrosion rates and erosional velocity ratios with risk factors to help you easily identify potential problems. You can define customized threshold values, and the risk can be visualized on the GIS map.

Custom ESP motors can now be added to catalog

A more accurate option to calculate the power consumption and transmission losses from downhole to surface for an ESP was added in PIPESIM 2019.5. Further, the set of catalogs in the PIPESIM simulator was expanded with motor and cable catalogs. In PIPESIM 2020.1, if the actual ESP motor cannot be found in the PIPESIM simulator catalog: You can add this custom motor to the ESP motor catalog.

PIPESIM 2020.1 includes several bug fixes and improvements. Some of them are listed below.PIPESIM 2020.1 includes several bug fixes and improvements. Some of them are listed below.

- Previously, the Network optimizer failed to converge if you had defined constraints for an inactive sink. Now, the PIPESIM UI ignores possible constraints for inactive sinks when writing to the engine file.

- When creating new items in a catalog, you can now copy data from MS Excel and paste it into the property tables, for example, on the Performance data tab. This is applicable to all catalogs where you can add items.

- In previous versions, gas lift valves with valve status Closed could have a non-zero value for Qgiv (gas rate) on the Diagnostics results tab. Now, Qgiv is zero for closed gas lift valves.

- If you had deselected the Float windows option and then changed the ESP slippage factor in Simulation settings, the ESP performance tables and curves were not updated. Also, PIPESIM duplicated the curves if the operating frequency was changed. Now, the tables and curves are automatically refreshed when you change the ESP slippage factor.

- The power derating factor for an ESP is read-only. Hence, this property is removed from the Artificial lift tab in the well editor.

- In Network simulation, a check valve would appear on the Profile results tab and cause a shift in the equipment name and reported results for the relevant flowline. As check valves do not have any results, they are now omitted from the profile results. This fix also corrects possible missing result gradients on the GIS map.

- A validation has been added for model component names containing comma. The validation message is now Name cannot start or end with a blank space, nor can it contain any invalid file-system characters or the characters: ; ' ,.

- If you had selected a custom unit for Back Pressure Equation under Options, any change to the value of Constant C on the Completions tab in the well editor was ignored. Now, the change is kept in the PIPESIM UI and it is also reflected in the output details after running the task.

- In ESP design, the Description shown on the Actual pump performance curve tab did not match the values for Pump parameters on the Results tab. Now, there is correspondence between the reported pump parameters and the Description.

- For Nodal analysis, the limit to how many completions can be shown on the System results tab has been significantly increased when you select IPR curves by layer. As several variables are included for each completion, there still is a limit on how many completions can be shown. The limit depends on the type of completion as well as the other types of equipment and output variables in the case.

- In PIPESIM Python Toolkit, when you used the export well model function to export a single well from a network model, the units catalog table was not exported with the well. This is now fixed.PIPESIM 2020.1 Release notes Page 5Schlumberg er-Private

- In Gas lift diagnostics, for a naturally flowing well, you might get a different solution in a simulation run with fixed injection pressure and fixed injection rate using the casing head pressure calculated from a run based on the same fixed injection rate. The solution algorithm is now changed to use a better initial guess to, if possible, avoid the solution with zero injection gas.

- In Network simulation, when Location of well boundary conditions is set to Surface on the Boundary conditions tab, the correct pressure and temperature are now reported for node results. Previously, the conditions at branch end instead of at branch inlet were reported.

- For PIPESIM Python Toolkit, there was a mismatch in the unit reported for, for example, HoldupFractionLiquid from result.profile_units and when executing result.profile. The unit was reported as % while the results were given as fractions. Any output variable with unit % should now be reported correctly.

- The allowed maximum value for sub-code TEMPERATURE in the NODE maincode is increased to 1000°F to make it consistent with the PIPESIM UI.

Fit-for-purpose modern production systemsensure that fluids are cost-effectively transported with the highest possible safety from the reservoir to the processing facilities. Harsh environments such as deepwater fields with complex infrastructure or large-scale onshore developments pose many additional challenges that must be addressed by the production system design. The ability to accurately simulate such a broad range of scenarios and conditions has established the PIPESIM steady-state multiphase flow simulator as the industry's leading tool for production system design.

Once production systems are brought into operation, the ability to ensure optimal production is critical to achieving the maximum economic potential of the asset. The PIPESIM simulator provides a comprehensive set of workflows ranging from candidate well selection for workovers to identification and mitigation of flow assurance challenges to online optimization of the complete system.

The modernized user interface (UI) delivers a step change in user experience, enabling users to build models more quickly and focus on results. The ability to work within one application and switch between well-centric or network-centric application layouts simplifies the modeling of the entire production system.

From early field development and all the way to production operations, the PIPESIM simulator enables production optimization over the complete life cycle by accessing the latest targeted science to address flow assurance challenges.

PIPESIM How-to Video Series

Schlumberger is the world's leading providerof technology and digital solutions for reservoir characterization, drilling, production, and processing to the energy industry. With product sales and services in more than 120 countries and employing approximately 82,000 people as of the end of third quarter of 2020 who represent over 170 nationalities, Schlumberger supplies the industry's most comprehensive range of products and services, from exploration through production, and integrated pore-to-pipeline solutions that optimize hydrocarbon recovery to deliver reservoir performance sustainably.

Product:Schlumberger PIPESIM

Version:2020.1.717

Supported Architectures:x64

Website Home Page :Languages Supported:englishKod:http://www.software.slb.com]www.software.slb.com

System Requirements:PC *

Size:598.8 mb

Download link:Kod:rapidgator_net: https://rapidgator.net/file/d4d1d6c0c03f240bcca72a5ea905e107/8tw19.Schlumberger.PIPESIM.2020.1.rar.html nitroflare_com: https://nitroflare.com/view/0EF5E2D15C5EFE9/8tw19.Schlumberger.PIPESIM.2020.1.rarLinks are Interchangeable - No Password - Single Extraction

1 sonuçtan 1 ile 1 arası

-

22.07.2021 #1Üye

- Üyelik tarihi

- 20.08.2016

- Mesajlar

- 136.029

- Konular

- 0

- Bölümü

- Bilgisayar

- Cinsiyet

- Kadın

- Tecrübe Puanı

- 144

Schlumberger PIPESIM 2020.1

Konu Bilgileri

Users Browsing this Thread

Şu an 1 kullanıcı var. (0 üye ve 1 konuk)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Alıntı

Alıntı

Konuyu Favori Sayfanıza Ekleyin